Franchises in the beauty, wellness, and pet care industries are facing an undeniable reality: to...

Inventory Forecasting for Multi-Location Brands: How to Order the Right Products at the Right Time

For multi-location service brands, inventory is one of the most important—and most expensive—parts of running a smooth operation. Yet most teams still rely on the same manual habits: eyeballing shelves, reordering everything when it “looks low,” or refilling SKUs back to a static max level.

The result? Too much of what isn’t selling, and not enough of what actually drives revenue.

Inventory forecasting changes that. By using real consumption patterns to predict upcoming product needs, multi-location brands can order exactly what they’ll need—when they’ll need it—and avoid the costly swings of overstocking and stockouts.

Below, we break down why forecasting matters, how it works in MyTime, and what it means for franchise operators aiming to run lean, profitable, and predictable operations.

What Is Inventory Forecasting?

Inventory forecasting is MyTime’s AI-driven solution leveraging historical usage patterns to predict what products your locations will need in the future. Instead of relying on guesswork or last month’s numbers, forecasting ensures your teams order the right amount of product at the right time.

For multi-location brands, this helps prevent two expensive problems:

(1) excess inventory that ties up cash, and (2) stockouts that interrupt services and reduce revenue.

Why Inventory Forecasting Matters

- Prevents over-ordering that ties up cash

- Reduces stockouts that disrupt services and sales

- Aligns purchasing with real consumption—not guesswork

- Standardizes purchasing across every location

- Improves profitability, accuracy, and operational predictability

If your brand has more than a handful of locations, forecasting becomes essential—not optional.

.png?width=2000&height=900&name=$%20(1).png)

Why Inventory Planning Breaks Down at Scale

As brands grow, inventory challenges get more complex—not less. Three operational pain points show up again and again:

1. Overstock Drains Cash

Overbuying feels safe in the moment, but it’s expensive over time.

- Shelves fill with slow-moving SKUs

- Shrink, expiration, and storage costs increase

- Capital that could support marketing, hiring, or expansion becomes trapped in product

Across a large footprint, even small miscalculations add up quickly.

2. Stockouts Limit Revenue and Hurt Trust

Stockouts are equally costly—but in the opposite direction.

- Required products run out, delaying or cancelling services

- Retail shelves sit empty, reducing per-visit revenue

- Members lose trust if their preferred products are frequently unavailable

Reputation damage is hard to quantify, but operators feel it.

3. Manual Ordering Doesn’t Scale

What works for one location breaks down across 10, 50, or 200.

- Managers rely on gut feel or visual checks

- Decision-making varies wildly between locations

- No shared logic or systemwide view

- No visibility into broader consumption trends

Manual ordering becomes a patchwork—one that gets more costly every time the brand grows.

Why Forecasting Works Better Than Traditional Ordering

Forecasting solves the weaknesses of static min/max rules and manager intuition.

Here’s why:

- Static rules can’t keep up. They treat every SKU the same—even if demand is rising, falling, or seasonal.

- Consumption patterns reveal the real story. Forecasting identifies trends you’d never see from a shelf check.

- Automation removes bias. Human judgment tends to favor recent usage; forecasting uses a full history of data.

- Faster, more consistent decision-making. Less time spent counting, more time running the business.

Forecasting brings structure, speed, and accuracy—three things manual ordering can’t match.

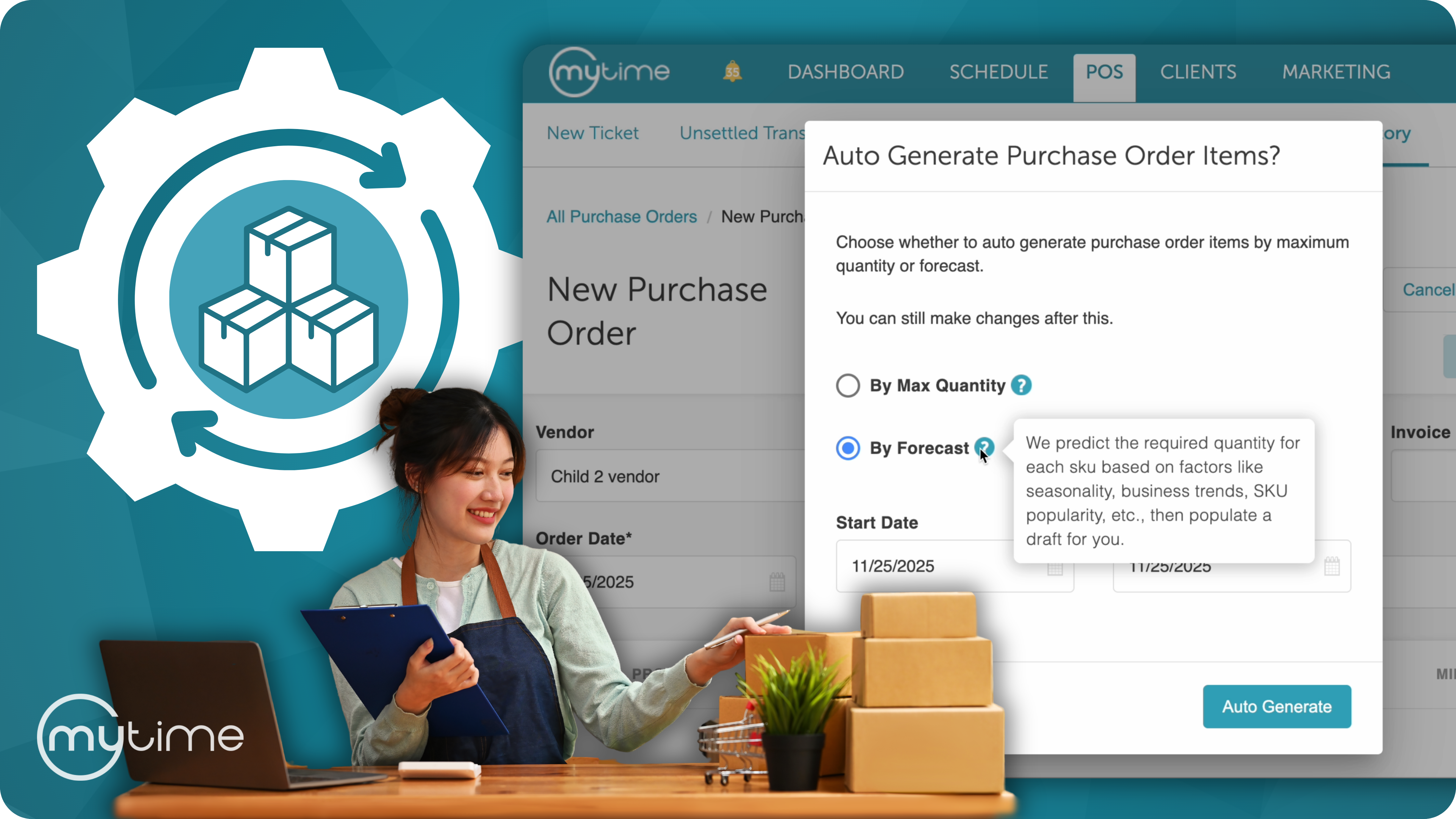

How MyTime Inventory Forecasting Works

MyTime applies AI-driven forecasting specifically for multi-location service brands, using real consumption data linked to both services and retail sales.

Here’s how it works:

1. Forecasting Built on Real Consumption Trends

MyTime evaluates usage across multiple windows—30, 60, 90 days, and up to one year when possible. This helps surface:

- Seasonal spikes

- Consistent trends

- Changing demand (rising or falling)

- Regional differences

Forecasts are built on real activity, not assumptions.

2. Eligibility Rules Ensure Reliable, Data-Backed Predictions

Not every product has enough data to produce a reliable forecast.

To keep predictions accurate at scale, MyTime evaluates each SKU’s activity against configurable criteria to determine eligibility for forecasting.

MyTime uses the following eligibility rules to determine which SKUs qualify:

- Lookback window (90/180/365 days): how far back MyTime reviews usage for each SKU

- Minimum number of days with sales or consumption: ensures the SKU has enough real activity to model upcoming needs (e.g., a product sold only twice in 90 days isn’t forecasted and instead follows Max logic).

These rules decide which SKUs qualify for forecasting based on available data, protecting teams from inaccurate predictions and keeping forecasts focused on products with meaningful activity.

3. A Built-In Safeguard for SKUs With Limited Data

If a product doesn’t qualify for forecasting, MyTime automatically replenishes it using Max logic—ensuring nothing slips through the cracks.

Max logic:

Replenishes products up to the franchise-set maximum stock levels, while respecting vendor requirements such as minimum order quantities (MOQs).

4. Optimized Ordering in One Streamlined Purchase Order

MyTime consolidates all recommended quantities into a single draft PO:

- Forecast quantities for SKUs that met the eligibility threshold

- Max quantities for SKUs that did not qualify for forecasting

No duplicate workflows. No missed items. No switching between modes.

5. Full Visibility Into the Data Behind Every Recommendation

SKU-level charts are surfaced exactly where operators need them during ordering, giving quick access to the data behind each recommendation:

- Historical usage (30/60/90 days)

- Seasonality and consumption patterns

- Forecasted demand for the selected date range

Managers understand not just what to order, but why.

-1.png?width=2000&height=900&name=Untitled%20design%20(62)-1.png)

What This Means for Franchise Operators

1. A More Profitable Inventory Mix

You keep the products that move and reduce the ones that don’t. Margins improve almost immediately.

2. Less Cash Trapped on Shelves

Lean, data-backed replenishment frees up capital for growth initiatives.

3. Fewer Stockouts and Emergency Orders

Locations stay prepared for demand—especially seasonal or sudden spikes.

4. Predictable Service Delivery

Clients get the same consistent experience across every location.

5. Managers Reclaim Time

No more spreadsheets, double-checking shelves, or manual guesswork.

6. Brand-Wide Consistency

Every location follows the same logic, improving financial performance and trust in the system.

Using Forecasting to Optimize Both Staffing and Inventory at Scale

Inventory Forecasting becomes even more powerful when paired with MyTime’s Labor Forecasting. Together, they give franchises a forward-looking view into both product needs and staffing requirements—two of the biggest drivers of operational efficiency.

Combined, they help operators:

- Predict upcoming service volume

- Align staffing and product needs based on real demand

- Plan weeks ahead with greater accuracy

- Strengthen unit economics across every location

This is the foundation of predictive operations—a smarter way to run a multi-location business.

FAQs: Common Questions About Inventory Forecasting

How accurate is inventory forecasting?

MyTime generates highly reliable forecasts for SKUs with sufficient activity. Only products that meet the eligibility rules are forecasted.

What data does MyTime use?

Historical consumption, service volume, seasonality, SKU popularity, and recent velocity—analyzed through AI-driven forecasting models.

What if a SKU doesn’t have enough history?

It automatically uses Max logic for replenishment.

Can managers override recommendations?

Yes. Operators can review and adjust any quantity before submitting the purchase order.

How do Forecast and Max quantities work together?

Both flow into a single, consolidated purchase order.

CTA — Upgrade to Predictive Inventory Planning

If your teams are still relying on spreadsheets, min/max rules, or gut feel, you’re leaving margin, cash flow, and consistency on the table. Inventory Forecasting changes that.

MyTime gives multi-location brands a smarter, demand-driven way to order the right products at the right time—reducing cost, protecting revenue, and creating a unified, predictable operational model across every location.

→ Schedule a personalized demo and see inventory forecasting in action.

.png?height=200&name=Copy%20of%20Strategic%20Shift%20Email%202%20(2).png)